Groundbreaking study shows defects spreading through diamond faster than the speed of sound

Defects can make a material stronger or make it fail catastrophically. Knowing how fast they travel can help researchers understand things like earthquake ruptures, structural failures and precision manufacturing.

By Glennda Chui

Settling a half century of debate, researchers have discovered that tiny linear defects can propagate through a material faster than sound waves do.

These linear defects, or dislocations, are what give metals their strength and workability, but they can also make materials fail catastrophically – which is what happens every time you pop the pull tab on a can of soda.

The fact that they can travel so fast gives scientists a new appreciation of the unusual types of damage they might do to a broad range of materials in extreme conditions – from rock ripped apart by an earthquake rupture to aircraft shielding materials deformed by extreme stress, said Leora Dresselhaus-Marais, a professor at the Department of Energy’s SLAC National Accelerator Laboratory and Stanford University who co-led the study with Professor Norimasa Ozaki at Osaka University.

“Until now, no one has been able to directly measure how fast these dislocations spread through materials,” she said. Her team used X-ray radiography – similar to medical X-rays that reveal the inside of the body – to clock the speed of the propagating dislocations through diamond, yielding lessons that should apply to other materials, too. They described the results today in Science.

Chasing the speed of sound

Scientists have been debating whether dislocations can travel through materials faster than sound does for nearly 60 years. A number of studies concluded that they could not. But some computer models indicated that yes, they could – provided that they started out moving at faster-than-sound speed.

Getting them instantaneously up to this speed would require a tremendous shock. For one thing, sound travels a lot faster through solid materials than it does through air or water, depending on the nature and temperature of the material, among other factors. While the speed of sound through air is generally given as 761 mph, it’s 3,355 mph through water and an incredible 40,000 mph in diamond, the hardest material of all.

Complicating things even more, there are two types of sound waves in solids. Longitudinal waves are like the ones in air. But because solids put up some resistance to the passage of sound, they also host slower-moving waves known as transverse sound waves.

Knowing whether ultrafast dislocations can break either of these sound barriers is important from both the fundamental science and practical points of view. When dislocations move faster than sound speed, they behave quite differently and result in unexpected failures that have thus far only been modeled. Without measurements, no one knows how much damage those ultrafast dislocations can do.

“If a structural material fails more catastrophically than anyone expected because of its high rate of failure, that’s not so good,” said Kento Katagiri, a postdoctoral scholar in the research group and first author of the paper. “If it’s a fault rupturing through rock during an earthquake, for instance, it could cause more damage to everything. We need to learn more about this type of catastrophic failure.”

The results of this study, Dresselhaus-Marais added, “could suggest that what we thought we knew about the fastest possible materials failure was wrong.”

The pop-top effect

To get the first direct images of how fast dislocations can travel, Dresselhaus-Marais and her colleagues performed experiments at the SACLA X-ray free-electron laser in Japan. They did the experiments on tiny crystals of synthetic diamond.

Diamond offers a unique platform to study how crystalline materials fail, Katagiri said. For one thing, its deformation mechanism is simpler than those observed in metals, making it easier to interpret these challenging ultrafast X-ray imaging experiments.

“To understand the damage mechanisms, we need to identify features in our images that are unambiguously dislocations, and not other types of defects,” he said.

When two dislocations meet, they attract or repel each other and generate even more dislocations. Pop open a can of soda made from an aluminum alloy, and the many dislocations that are already in the lid – created when it was shaped into its final form – interact and spawn new dislocations by the trillions, which cascade into absolute critical failure as the top of the can flexes and the pop top snaps open. Those interactions and how they behave govern all the mechanical properties of materials we observe.

“In diamond, there are only four types of dislocation, while iron, for instance, has 144 different possible types of dislocations,” Dresselhaus-Marais said.

Diamond may be much harder than metal, the researchers said. But much like a soda can, it will still bend by forming billions of dislocations if it’s shocked hard enough.

Making X-ray images of shock waves

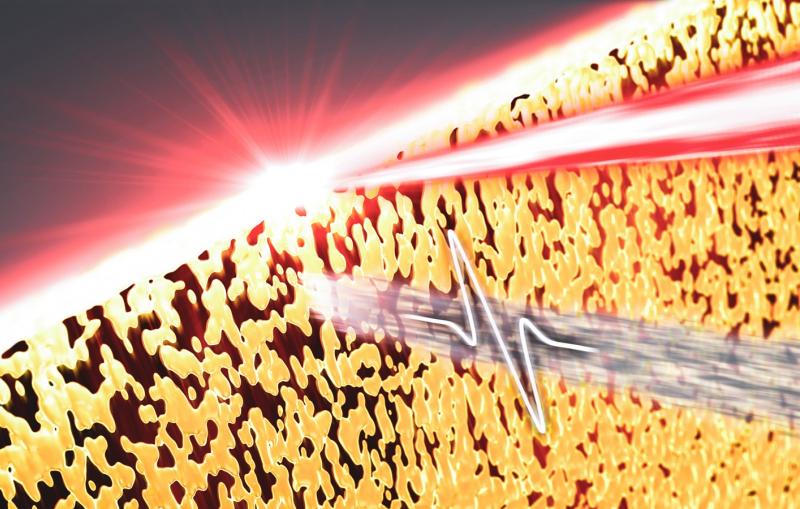

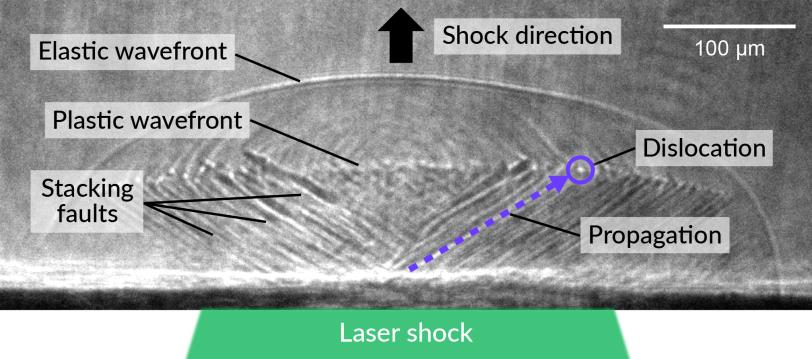

At SACLA, the team used intense laser light to generate shock waves in diamond crystals. Then they essentially took a series of ultrafast X-ray images of the dislocations forming and spreading on a timescale of billionths of a second. Only X-ray free-electron lasers can provide X-ray pulses short enough and bright enough to capture this process.

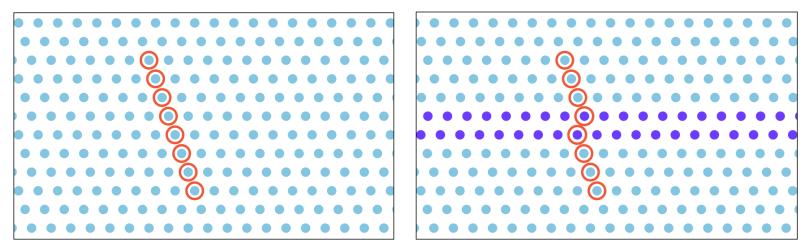

The initial shock wave split into two types of waves that continued to travel through the crystal. The first wave, called an elastic wave, temporarily deformed the crystal; its atoms bounced back into their original positions right away, like a rubber band that’s been stretched and released. The second wave, known as a plastic wave, permanently deformed the crystal by creating small errors in the repeating patterns of atoms that make up the crystal structure.

These tiny shifts, or dislocations, create “stacking faults” where adjacent layers of the crystal shift with respect to each other so they don’t line up the way they should. The stacking faults propagate outward from where the laser hit the diamond, and there is a moving dislocation at the leading tip of each stacking fault.

With X-rays, the researchers discovered that the dislocations spread through diamond faster than the speed of the slower type of sound waves, the transverse waves – a phenomenon that had never been seen in any material before.

Now, Katagiri said, the team plans to go back to an X-ray free-electron facility, such as SACLA or SLAC’s Linac Coherent Light Source, LCLS, to see if dislocations can travel faster than the higher, longitudinal speed of sound in diamond, which will require even more powerful laser shocks. If and when they break that sound barrier, he said, they will be considered truly supersonic.

Leora Dresselhaus-Marais is an investigator with the Stanford Institute for Materials and Sciences (SIMES) at SLAC and the Stanford PULSE Institute. Researchers from Osaka University, the Japan Synchrotron Radiation Research Institute, RIKEN SPring-8 Center and Nagoya University in Japan; DOE’s Lawrence Livermore National Laboratory; Culham Science Center in the UK; and École Polytechnique in France also contributed to this research. Major funding came from the U.S. Air Force Office of Scientific Research.

Citation: Kento Katagiri et al., Science, 6 October 2023 (10.1126/science.adh5563)

For questions or comments, contact the SLAC Office of Communications at communications@slac.stanford.edu.

About SLAC

SLAC National Accelerator Laboratory explores how the universe works at the biggest, smallest and fastest scales and invents powerful tools used by researchers around the globe. As world leaders in ultrafast science and bold explorers of the physics of the universe, we forge new ground in understanding our origins and building a healthier and more sustainable future. Our discovery and innovation help develop new materials and chemical processes and open unprecedented views of the cosmos and life’s most delicate machinery. Building on more than 60 years of visionary research, we help shape the future by advancing areas such as quantum technology, scientific computing and the development of next-generation accelerators.

SLAC is operated by Stanford University for the U.S. Department of Energy’s Office of Science. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time.